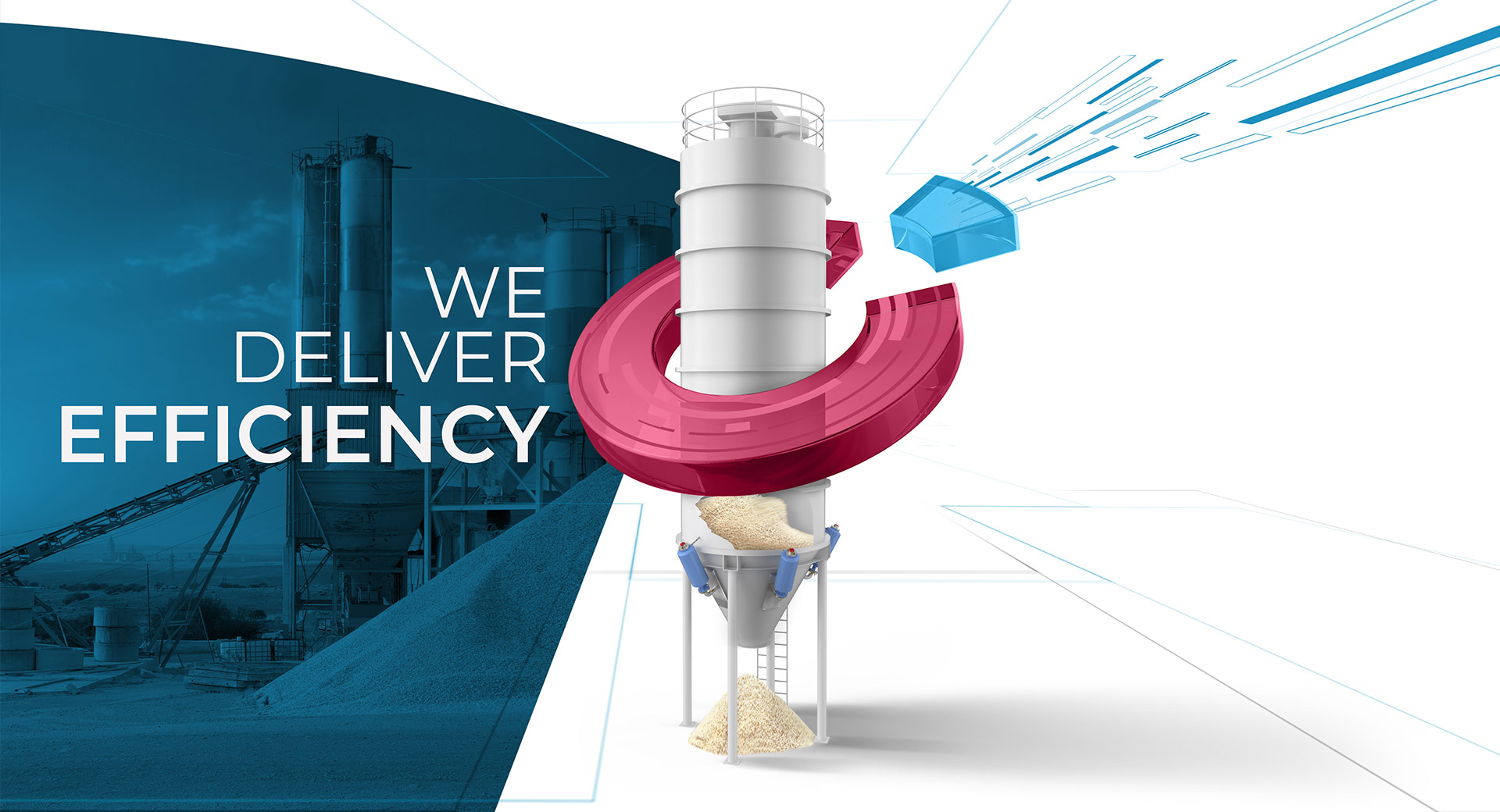

Bulk solid material

handling solutions

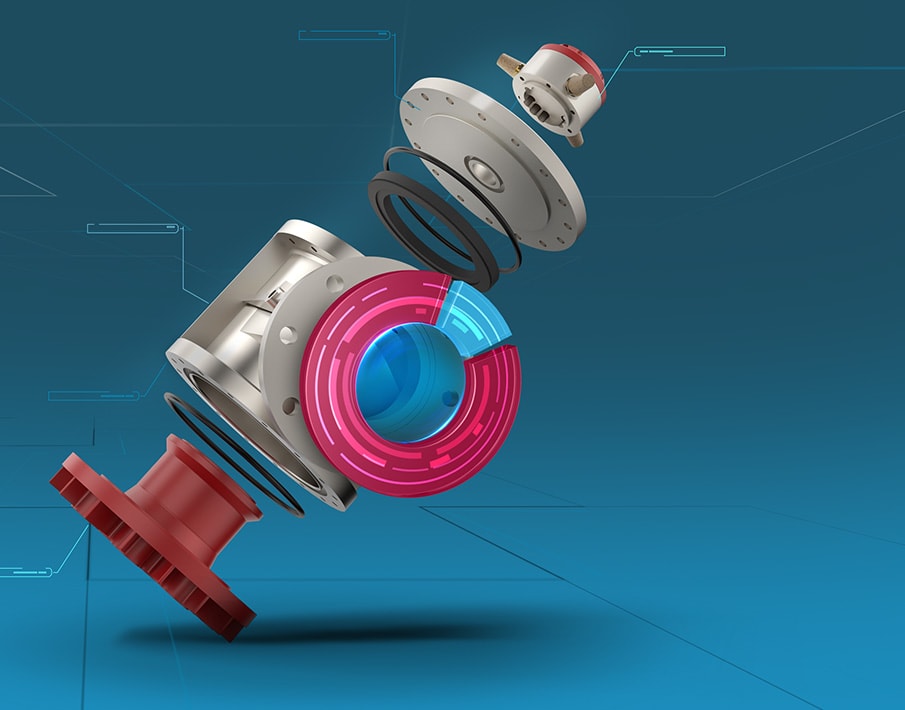

AIRFLASH®

per fluidificazione materiali stoccati e rimozione depositi.

Bulk solid material

handling solutions

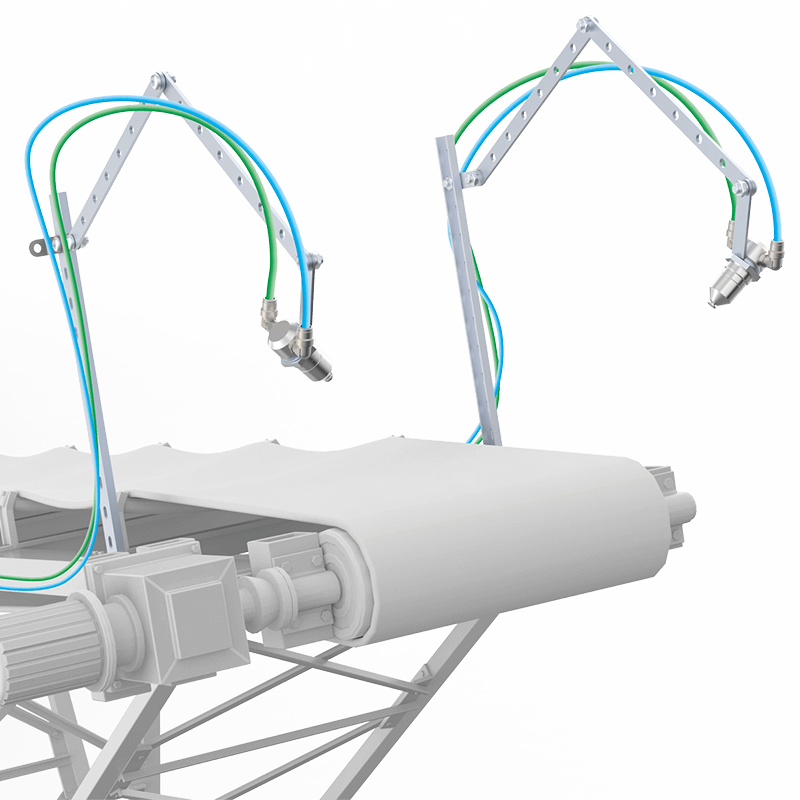

ECOFOG®

Nebulizzazione di acqua a basse pressioni per la captazione di polveri industriali.

Bulk solid material

handling solutions

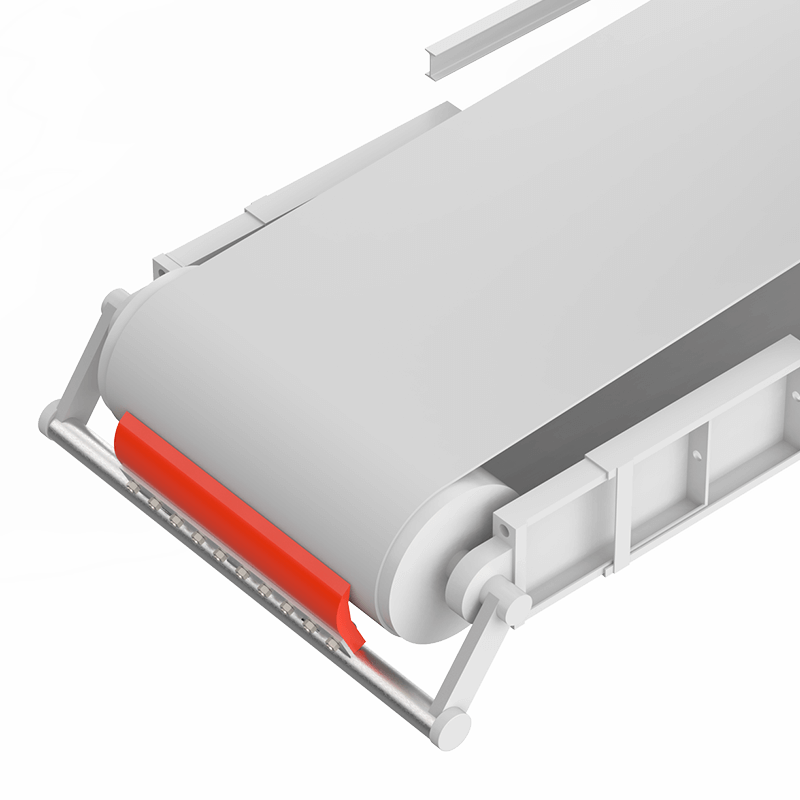

RASKIA®

Elementi raschianti per azione pulente con aderenza continuativa su nastri trasportatori.