for your production plant

AIRFLASH®

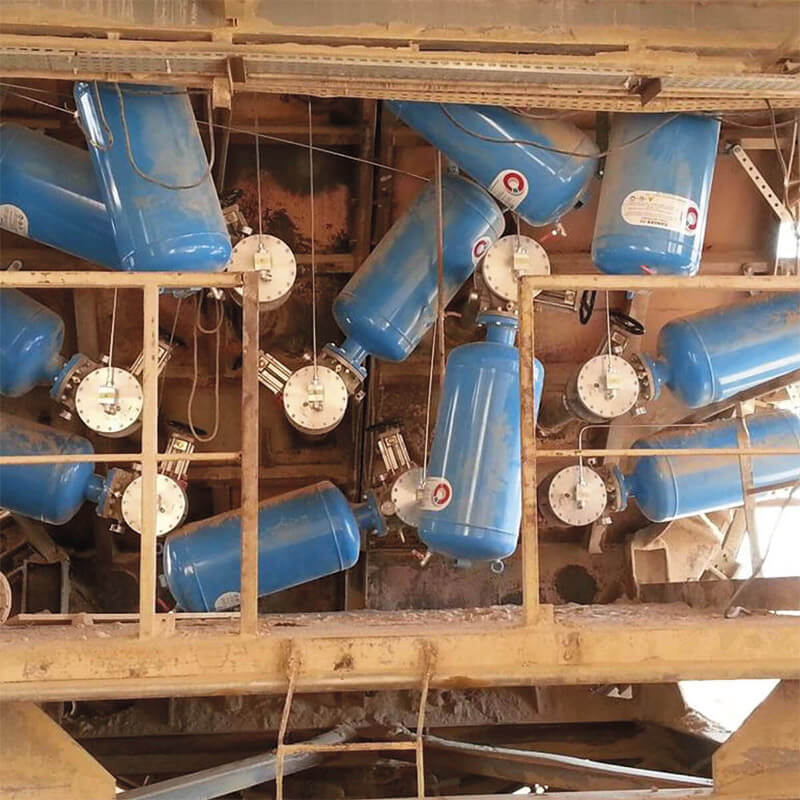

- It guarantees the efficiency of the storage structures and dust ducts, preventing the formation of encrustations and occlusions

- It guarantees the continuous and regular flow of material in the production chain, eliminating and preventing the formation of blockages, encrustations, accumulations, bridges and rat-holes that hinder the transit of material

- Protects the operators safety: AIRFLASH has a preventive action on the formation of clogging and eliminates the need for maintenance to manually unblock the occlusions

- It reduces unscheduled downtime

- It fluidifies and periodically moves the stored material, helping the continuous material replacement in a first-in first-out logic

- Limits the risk of deterioration for organic materials by eliminating "dead zones" in which the material stagnates (fundamental function in the management of organic material)

- It performs a cleaning action that reduces the risk of contamination between different materials passing one after the other

It can be applied on materials with different nature and grain size, from organic to inorganic, from material with medium and large grain size to material with fine and/or powdery grain size.